When it comes to using RFID technology, one of the biggest challenges is getting a tag to work on or around metal surfaces. Metal can interfere with the radio waves used to transmit information from an RFID anti-metal tag, making it difficult to read the tag’s data.

However, you can improve the performance of RFID tags on metal surfaces. This article evaluates the effects of metal on RFID and best practices for using RFID tags on or around metal surfaces.

RFID on Metal – Why is It Tricky?

RFID tags contain a chip that stores information about the item to which it is attached. This information is transmitted to an RFID reader via radio waves. The reader then uses this information to track the item or perform other functions.

The problem is that metal surfaces can interfere with the radio waves used to transmit information from an RFID tag to the reader. This interference can make it difficult, or even impossible, for the reader to receive and interpret the information from the tag.

There are a few reasons why metal causes this interference:

- Metal surfaces can reflect radio waves, making it difficult for the waves to reach the tag.

- Metal surfaces can absorb radio waves, preventing the waves from reaching the tag.

- Metal surfaces can conduct electricity, creating electrical noise that interferes with the signal from the tag.

Because of these reasons, it can be difficult to get RFID tags to work on metal surfaces. However, you can circumvent the problem using a few hacks.

Some Ways to Improve RFID Performance on Metal Surfaces

While there is no guaranteed way to make RFID work perfectly on metal surfaces, there are a few things you can do to help improve performance. They include:

- Use Metal Mount RFID Tags

Some RFID tags are specifically designed to be used on metal surfaces. These tags have a special mounting system that helps reduce the effects of metal interference.

For example, some manufacturers offer RFID Anti-Metal tags with a gap between the tag and the metal surface. This gap helps to reduce interference by allowing radio waves to pass through without being reflected or absorbed by the metal.

- Use a Low-Frequency RFID System

One way to reduce the effects of metal interference is to use a low-frequency RFID system. These systems operate at frequencies less likely to be affected by metal surfaces.

For example, most low-frequency RFID systems operate at 125 kHz or 134.2 kHz. These frequencies have a longer wavelength than higher frequencies, which makes them less likely to be affected by metal surfaces.

However, they have a lower data transfer rate, which may not be suitable for all applications. If you want the benefits of high data transmission, you should use HF or UHF metal-mount RFID tags. This way, you can still take advantage of the long wavelength while maintaining a high data transfer rate.

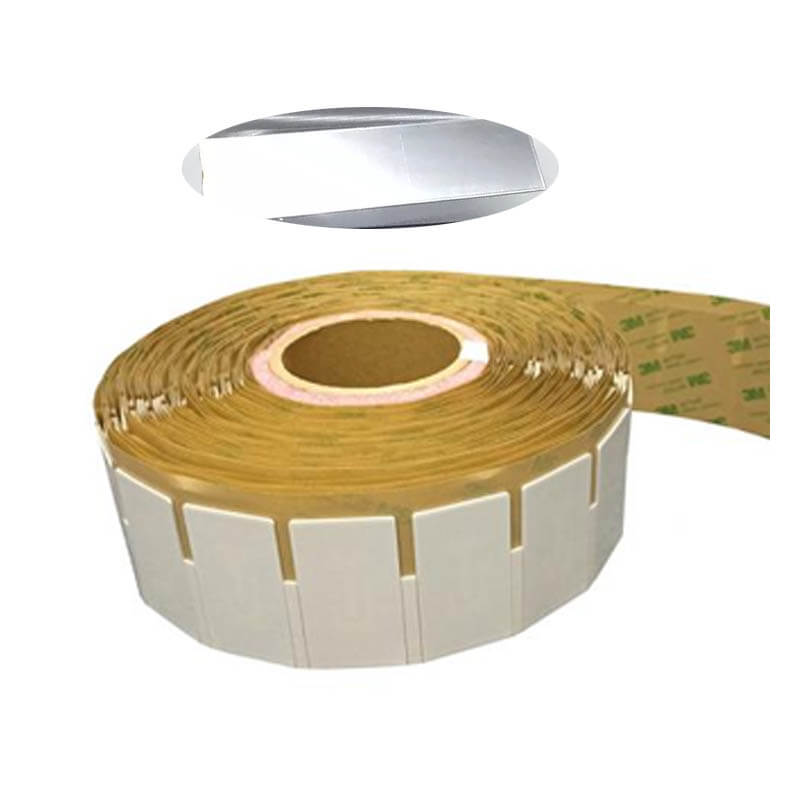

What is RFID Anti-Metal Tag?

An RFID anti-metal tag works optimally on or around metal surfaces. They are used in harsh or difficult environments where other tags would fail. As such, these tags are designed to be hardy. Some of their features include:

- High-Temperature Tolerance. These tags can withstand high temperatures of up to 200 ℃. This property is useful in applications where the tags will be exposed to extreme heat, such as in a foundry.

- Corrosion Resistance. RFID anti-metal tags are also designed to resist corrosion. This resistance is critical in applications where the tags will be exposed to corrosive materials, such as chemicals or salt water.

- Flexibility. These tags are also flexible, making them ideal for applications where they need to conform to a curved surface.

- High Stability. RFID anti-metal tags have high stability, meaning they retain their properties even after exposure to extreme conditions.

- Good Read Performance. Anti-metal RFID tags have good read performance. This is critical since most of these tags are used outdoors or in other difficult environments.

- Superior Protection. RFID anti-metal tags offer superior protection against physical and environmental damage. This protection is crucial in applications where the tags will be exposed to harsh conditions, such as on a construction site. The protection ranges from IP63 to IP68.

How to Use RFID Anti-Metal Tags?

RFID anti-metal tags can be used in a variety of applications. Some of the most common include:

- Asset Tracking. These tags track assets, such as equipment or tools. This is especially useful in construction or manufacturing where there is a need to track the location of equipment.

- Inventory Management. RFID anti-metal tags can be used in warehouses or retail stores to track metallic inventory. This way, you can know what is in stock and where it is located.

- Vehicle Tracking. These tags can be used to track vehicles. This is useful for fleet management or security purposes.

How to Attach RFID Tags on Metal Surfaces?

The attachment method you use will depend on the type of RFID tag you are using. For example, some RFID tags come with a special adhesive designed for use on metal surfaces.

It is also necessary to consider the environment where the tag will be used. For example: If the tag will be exposed to high temperatures, you will need to use a method that can withstand those temperatures.

Some attachment methods include:

- Adhesives. Adhesives are a common method for attaching RFID tags to metal surfaces. However, not all adhesives are suitable for use on metal. You must use an RFID tag with a special adhesive designed for use on metal.

- Welding. Welding is another effective method for attaching RFID tags to metal surfaces. This method is often used in applications where the tag will be exposed to high temperatures.

- Bolting. Bolting is another common method for attaching RFID tags to metal surfaces. This method is often used in applications where the tag will be exposed to high temperatures.

Whichever attachment method you choose; it is critical to test the tag before using it in your application. This will eliminate any potential problems that could affect its functionality.

Related articles:

- What are RFID Standards? An All-Inclusive Guide

- 12 Best NFC Tag Uses That Will Make Your Life Fun

- A Guide to Buying RFID tags and Equipment.

- 6 Crucial Factors that Affect RFID Read Range – A Detailed Guide

- LF, HF, and UHF Frequency: What’s the Difference?

- What Are RFID Tags and How Are They Used?

- Tool Tracking – RFID Tags for Tools

- 10 Ways RFID Technology is Already in Your Life!