RFID (Radio Frequency Identification) tire tags are small electronic devices embedded or attached to tires that contain a chip and antenna that communicate wirelessly with an RFID reader. These tags store unique identifiers and other data that enable businesses in the automotive, fleet management, manufacturing and retail industries to improve operational efficiency, safety and sustainability. The following section details how RFID tire tags are improving business performance through industry practices and innovation.

Enhanced Inventory Management

- Real-Time Tracking: RFID tire tags allow businesses to track tires throughout the supply chain—from manufacturing to distribution, retail, and end-user application. This real-time visibility reduces errors in inventory counts and ensures accurate stock levels. For example, retailers can instantly update inventory when tires are added or removed, saving time and improving accuracy.

- Streamlined Logistics: Automated RFID scanning reduces manual labor for tasks like checking incoming and outgoing shipments. This speeds up warehouse operations and minimizes errors in order fulfillment, such as loading the wrong tires onto trucks.

- Theft Prevention: Unique identifiers make it harder for tires to be stolen or sold on the gray market, protecting revenue and brand integrity.

Business Impact: Improved inventory accuracy reduces overstocking or stockouts, optimizes warehouse space, and lowers losses from theft or mismanagement, leading to cost savings and better customer service.

Improved Operational Efficiency

- Automated Data Collection: RFID tags eliminate manual data entry by automatically capturing tire information (e.g., serial number, manufacturing date, or specifications) when scanned. This speeds up processes like quality control, inspections, and maintenance scheduling.

- Fleet Management Optimization: For fleet operators, RFID tags provide detailed tire data, enabling proactive maintenance scheduling. For instance, Michelin’s Tire Care program, using RFID, reduced emergency roadside service calls by 55% for one fleet, saving $2,000 monthly.

- Error Reduction: Automated scanning prevents human errors, such as mismatching tires to vehicles or using incorrect tire types, ensuring compliance with specifications (e.g., matching tire IDs to vehicle VINs).

Business Impact: Automation reduces labor costs, minimizes downtime, and enhances operational reliability, allowing businesses to focus on core activities.

Enhanced Safety and Maintenance

- Proactive Maintenance: RFID tags, especially when paired with sensors (e.g., for pressure or temperature), enable real-time monitoring of tire conditions. This helps identify issues like wear or improper inflation before they lead to failures, improving vehicle safety and reducing accidents.

- Lifecycle Tracking: Tags store data on tire usage, repairs, and retreading history, helping mechanics make informed decisions about maintenance or replacement. For example, RFID supports precise tracking of tire wear, critical in high-stakes environments like NASCAR or aviation.

- Recall Management: In case of recalls, RFID tags provide detailed tire information (e.g., batch number, production date), making it easier to identify and replace affected tires, reducing liability and enhancing customer trust.

Business Impact: Enhanced safety reduces accident-related costs, improves compliance with regulations, and boosts customer confidence, while efficient recalls minimize reputational and financial risks.

Sustainability and Regulatory Compliance

- Efficient Recycling: RFID tags simplify tire sorting and recycling by providing data on tire condition and history, ensuring proper disposal or retreading. This supports a circular economy and reduces environmental impact.

- Compliance with Regulations: In regions like the EU, upcoming Ecodesign for Sustainable Product Regulations (ESPR) mandate Digital Product Passports (DPPs) for tires by 2028–2030. RFID tags, like Beontag’s Gen4 developed with Michelin, ensure compliance by enabling full lifecycle traceability.

- Retreading Support: Tags provide essential data for retreading, extending tire lifespan and reducing waste. This is particularly valuable for fleet operators and retreaders.

Business Impact: Sustainable practices lower environmental compliance costs, enhance corporate social responsibility, and attract eco-conscious customers, while retreading reduces replacement costs.

New Business Models and Customer Engagement

- Innovative Revenue Streams: RFID enables models like pay-per-mile or pay-per-use by tracking tire usage accurately. This can attract new customers and create recurring revenue for tire manufacturers or service providers.

- Improved Customer Service: Retailers and service centers can access tire specifications and history instantly, offering faster, more personalized service. For example, mechanics can recommend maintenance based on precise tire data, enhancing customer satisfaction.

- Anti-Counterfeiting: RFID’s unique, tamper-proof identifiers prevent counterfeit tires, protecting brand reputation and ensuring customers receive genuine products.

Business Impact: New business models diversify revenue, while improved service and authenticity build customer loyalty and trust, driving repeat business.

Quality Control and Manufacturing Efficiency

- Production Tracking: RFID tags enable precise tracking during tire manufacturing, ensuring quality control and reducing defects. For instance, tags can verify that tires meet specifications before leaving the factory.

- Mold and Tooling Management: High-temperature RFID tags track molds and tools, optimizing production processes and reducing downtime.

- Data-Driven Insights: Data collected from RFID tags can be analyzed to improve manufacturing processes, identify bottlenecks, and enhance product quality.

Business Impact: Higher quality reduces returns and warranty claims, while streamlined production lowers costs and improves output.

How to Implement RFID Tire Tags

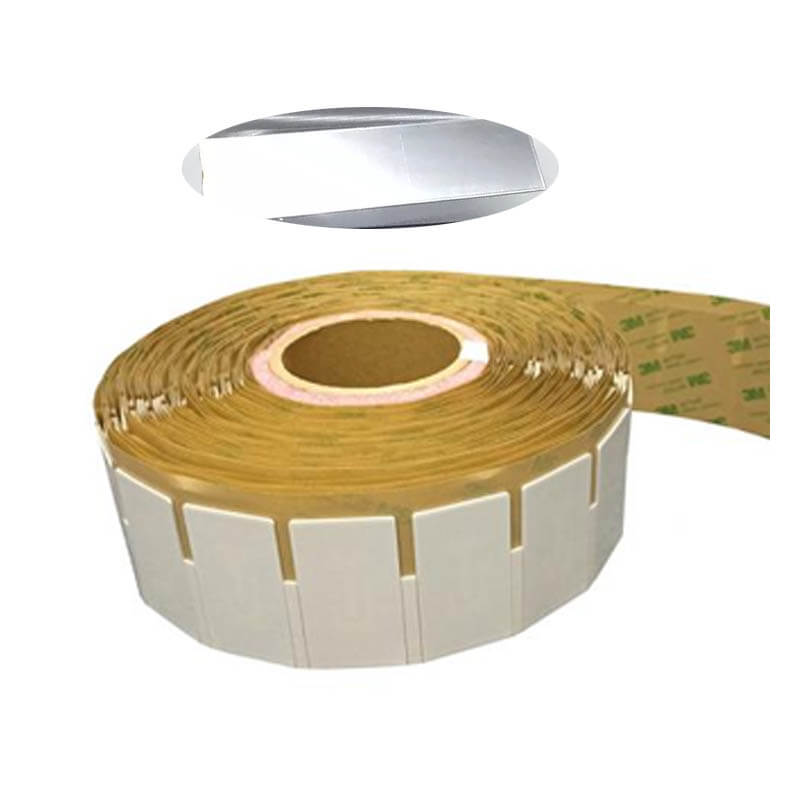

- Choose the Right Tag: Select durable tags (e.g., Hana RFID’s Linkless or Beontag’s Gen4) designed for tire vulcanization and harsh conditions. Ensure compliance with standards like ISO 20909–20912 or GS1 SGTIN-96.

- Integrate with Systems: Use RFID readers and software (e.g., Murata’s id-BridgeTM) to link tags to inventory, fleet, or maintenance systems. Cloud-based platforms like GDSO enable data sharing across manufacturers.

- Embed or Attach Tags: Embed tags during manufacturing for permanent tracking or attach aftermarket tags for existing tires. Ensure proper placement to maintain read performance.

- Train Staff: Educate employees on using RFID readers and interpreting data to maximize benefits.

- Monitor and Analyze: Use data analytics to gain insights into tire performance, inventory trends, and maintenance needs.

Challenges to Consider

- Initial Costs: RFID readers, tags, and system integration require upfront investment, though long-term savings often justify the cost.

- Reader Availability: Not all tire service centers have RFID readers, which may limit aftermarket benefits unless standardized.

- Privacy Concerns: RFID tags can raise privacy issues if misused (e.g., tracking vehicles without consent). Businesses should ensure compliance with data protection laws and inform customers about tag usage.

- Tag Durability: Tags must withstand vulcanization, road conditions, and retreading. Modern designs like Michelin’s Gen4 address this with flexible antennas and robust construction.

RFID tire tags transform business performance by streamlining inventory, enhancing safety, supporting sustainability, and enabling innovative business models. From manufacturing to recycling, they provide end-to-end traceability, reduce costs, and improve customer satisfaction. Companies like Michelin, Continental, and Hana RFID are leading the way, with millions of tires already equipped. To implement RFID effectively, invest in compatible systems, choose durable tags, and align with industry standards. By adopting RFID tire tags, businesses can achieve operational excellence, meet regulatory demands, and drive sustainable growth in a competitive market.

Related articles:

- What are RFID Standards? An All-Inclusive Guide

- A Guide to Buying RFID tags and Equipment.

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- Benefits of Using RFID Technology in the Clothing Industry

- LF, HF, and UHF Frequency: What’s the Difference?

- 10 Ways RFID Technology is Already in Your Life!

- What Are RFID Tags and How Are They Used?