RFID tags are small devices that contain a chip and antenna. The chip stores information about the object to which it is attached, and the antenna enables the tag to communicate with an RFID reader.

RFID technology has three elements, including RFID tags, RFID readers, and RFID software. These elements work together to track, manage, and store data about RFID-tagged objects.

What are RFID Tags?

Before we look at the types, it’s worth defining what an RFID tag is. An RFID tag is a device that stores information about an object to which it is attached. The tag uses radio waves to communicate with an RFID reader, which sends the information to a computer for processing.

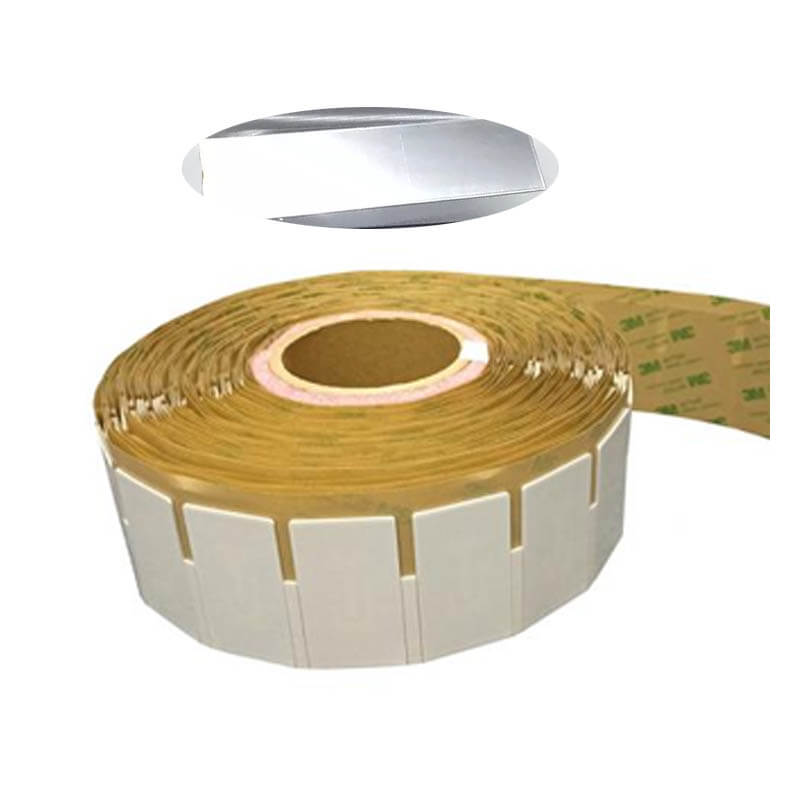

RFID tags come in a variety of shapes and sizes, and they can be made from different materials depending on their intended use. Some tags are as small as a grain of rice, while others are larger and more durable.

The architecture of an RFID tag typically includes three main components:

- RFID Chip. This is the smallest component of a tag. It has a memory that can store small amounts of data, primarily the object’s unique identification number. This number can be re-written (only for read/write tags), enabling the tag to be used multiple times.

- RFID Antenna. This component sends and receives radio waves, allowing the tag to communicate with an RFID reader. The size and shape of the antenna determine the range at which the tag can be read.

- Substrate or Housing. This part of the tag protects the chip and antenna from damage. It also determines the tag’s form factor and size. It can be made from different materials, including plastics and fabric.

These elements are typically encapsulated in a single unit, although the antenna may be separate from the chip and housing in some cases. However, they must all be in perfect working conditions for the tag to function properly.

Types of RFID Tags

While there are many different types of RFID tags, they can generally be classified based on:

- Source of Power. This refers to how the tag gets its power. Some tags have a built-in battery that powers the device, while others rely on the energy transmitted by the RFID reader to function.

- Memory Type. There are two main types of memory: read-only and read/write. Read-only tags pre-programmed chips with a unique identification number at the time of manufacture. This number cannot be changed or rewritten. On the other hand, Read/write tags have a blank chip that can be programmed with new data.

- Operating Frequency. RFID tags operate at different frequencies, depending on the specific application. The three main frequency ranges are low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). Each range has its advantages and disadvantages, which will be discussed in more detail later.

Classification Based on Power Source

RFID tags can be classified based on the source of power. The two main types of RFID tags are active and passive.

- Active RFID Tags

These tags have a built-in power source, usually a battery. This enables the tag to transmit radio waves over long distances, typically up to 100 meters.

Active tags are more expensive than passive tags and they require more maintenance. The battery life of active tags is limited, which means they need to be replaced more often.

These replacement requirements and high procurement costs make active tags less popular than passive tags. However, they are still used in applications where long read ranges are necessary, such as inventory management and asset tracking.

- Passive RFID Tags

These tags don’t have a built-in power source and they rely on the energy transmitted by the RFID reader to function. The RFID reader sends a radio wave that energizes the tag and powers it up. The tag uses this energy to transmit its signal back to the reader.

This technology is called inductive coupling. The distance between the tag and the reader determines how much power is transferred to the tag. If the tag is too far away, it won’t receive enough power to function.

Passive RFID tags are more affordable than active tags and they don’t require maintenance. As such, they are more popular than active tags. They are typically used in applications where short read ranges are sufficient, such as event management and supply chain tracking.

Classification Based on Memory Type

RFID tags can also be classified based on the type of memory. As mentioned earlier, there are two main types of memory: read-only and read/write.

- Read-Only RFID Tags

As the name suggests, these tags can only be read and cannot be rewritten. They can be pre-programmed with a unique identification number at the time of manufacture, or programmed later using an encoder.

Once encoded, the tag cannot be modified again. This is because the read-only memory is typically locked to prevent accidental or unauthorized changes.

Read-only RFID tags are less expensive than read/write tags and don’t require special programming devices. They are often used in applications where the data needs to be read but never changed, such as product identification.

They can also be used in ticketing where the data needs to be read, but the ticket cannot be reused. For example, a one-time-use event ticket cannot be copied or altered in any way.

They are usually cheap and available on a large scale, making them more popular for these types of applications. For example, world cup matches have used read-only RFID tags ticketing system to prevent ticket fraud and reduce cost.

- Read/Write RFID Tags

As the name suggests, these tags can be read and rewritten as needed. They have a blank chip that can be programmed with new data using a programmer.

Read/write RFID tags are more expensive than read-only tags and require special programming devices. They are often used in applications where the data needs to be read and updated regularly, such as employee management.

They can also be used in access control where the data is updated whenever a user is added/removed from the system. For example, an employee’s access privileges may be updated when they are promoted or transferred to a different department.

Classification Based on Frequency

This is probably the most vital classification because it determines the read range and other performance characteristics. RFID tags can operate at different frequencies, but the three most common are low frequency (LF), high frequency (HF), and ultra-high frequency (UHF).

- Low-Frequency RFID Tags (125-134.2 kHz)

LF tags have a short read range of around 10 cm (4 inches). They can only be read one at a time since they lack adequate anti-collision mechanisms.

Their data transmission rate is also slow, typically around 10 bits per second. This is because the LF signal has a low frequency which doesn’t carry much data.

LF tags are often used in applications where short read ranges are sufficient, such as livestock tracking (as defined by ISO 14223 and ISO/IEC 18000-2). They are also used in access control and asset management.

Their antennae are made of copper coils around a ferrous core. They are quite expensive to manufacture, making them relatively pricey.

- High-Frequency RFID Tags (13.56 MHz)

HF/NFC RFID inlays/ tags have a short read range of around 30 cm (12 inches) to 1 meter. They can be read one at a time or in groups since they have adequate anti-collision mechanisms.

Their data transmission rate is also slow, around 106 bits per second. Their antennae are made of aluminum, copper, or silver coils with 3-7 coils. There are cheaper to manufacture (compared to LF tags), making them more affordable.

They are controlled by various RFID standards, including ISO 15693 (asset tracking), ISO/IEC 14443 A & ISO/IEC 14443 (MIFARE), ECMA-340 & ISO/IEC 18092 (NFC), and JIS X 6319-4 (FeliCa).

This technology is applied in various areas, including contactless payments, public transportation, access control, and asset tracking.

- Ultra-High Frequency RFID Tags (868 MHz to 956 MHz)

UHF RFID inlays/tags have a long read range of around 1 meter to 10 meters. They can be read in groups since they have adequate anti-collision mechanisms.

Their data transmission rate is fast, making them suitable for large-scale applications. UHF tags are also relatively cheap to manufacture, making them more affordable.

They are easily affected by metal and water, which limits their applications. However, metal-mount RFID tags have been modified to overcome this challenge.

These tags can either be passive or active. RFID UHF passive tags harvest energy from the reader’s signal to power up and communicate. Active UHF RFID tags have their power source, typically a battery.

How to Attach RFID Tags to Objects?

FID tags can be attached to objects in many ways. The most common method is to use an adhesive. Adhesives are available in a variety of formulations, including permanent and removable.

Permanent adhesives are best suited for objects that will not be moved frequently. On the other hand, removable adhesives are best suited for objects that will be moved frequently.

Another common method for attaching RFID tags is to sew them onto objects. This is mostly used with RFID clothing tags and RFID laundry tags.

RFID tags can also be attached to objects using other methods, such as rivets, screws, and bolts. Choose the method that best suits your needs.

It is important to note that RFID tags can be attached to almost any object, regardless of its size, shape, or material. Just ensure that the tag is properly secured to the object to prevent it from being lost or damaged.

Benefits of Using RFID Tags

RFID tags offer many benefits over traditional barcodes, including the following:

Save time and money through automation

RFID applications can automatically track the movement of goods and upload the information to the ERP or financial management system. Therefore they can remove the need for manual form filling and replace outdated spreadsheets. The use of fixed readers at key points can save even more time – and on a production line, for example, can remove the need for manual intervention entirely.

Automated tracking is also possible when goods are transferred from one carrier to another, for example from road to rail. This enables real-time monitoring of goods in transit and prevents loss through theft or damage.

In addition, RFID tags allow you to locate assets such as pallets, boxes, or containers at any given time by reading their location via radio waves. This can be used for quick stock checks or even during larger operations such as disaster relief efforts where it is important to know where particular items are located at any given time.

Tracking assets and managing inventory

Tracking assets and materials is a challenge for most organizations – whether it is components on a production line, finished products being despatched, industrial containers that need returning, or tools, laptops, and other high-value equipment that often go missing.

Passive RFID Tags systems offer a fast and reliable way to track them without having to count each item.

With RFID applications you can immediately see how many items you have of any one type and their location or what stage they are at in the process. You can track items from the time they are received in stores, issued to manufacturing, and used in a finished item. This makes it easy to manage inventory, perform stock checks and audits, and control ‘shrinkage’. RFID can also help to find items that are on site but have been misplaced.

Enhancing health and safety

RFID systems allow companies to check when equipment and vehicles have been inspected or when the inspection is due, and restrict their use if certain conditions are not met. Systems like CheckedOK offer an efficient way to manage inspection and reporting regimes and help satisfy insurers or regulatory bodies that processes are being followed.

RFID systems can also be used to improve health and safety in the workplace by providing a low-cost system for tracking workers’ locations. This can help identify dangerous areas where workers need training or provide information about worker productivity.

Improving data accuracy and availability

Passive RFID Tags can be used to collect data on the location and status of assets, people, and vehicles. This can be used to improve health and safety. For example, asset tracking systems can help keep track of tools, equipment, and other assets so that they don’t get misplaced or stolen. It can also help ensure that equipment is returned to the correct location after use.

Enhanced quality and traceability

Passive RFID Tags offer enhanced quality and traceability in our product specialties. With the ability to track products through every step of production and beyond into distribution, Passive RFID Tags can provide valuable insights and improved visibility that ultimately helps us increase the safety and reliability of our products. As Passive RFID technology continues to grow, customers are increasingly looking for these tags on their products as a symbol of quality assurance. With Passive RFID Tags, we can guarantee our customers the highest level of quality possible.

Better control of production

Passive RFID tags have given factories the ability to gain greater control over the production process. They allow for the tracking of inventory, providing accurate data on product movement and when restocking is necessary.

By investing in Passive RFID tag technology, manufacturers can reduce waste and optimize workflow by having real-time insights into each stage of production. The cost savings associated with this type of system are substantial, making it an attractive proposition for companies looking to tighten their margins and lower their carbon footprints in today’s competitive market.

More in-depth management information

RFID technology is a valuable asset for businesses, allowing them to efficiently track and monitor their products throughout their entire lifecycle. Passive RFID Tags make this possible by providing real-time data capture, giving companies a clear understanding of their assets and products at each stage.

This immense power allows businesses to make informed decisions when it comes to operational planning and enhances the process of boosting efficiency. Overall, RFID is the perfect tool for anyone looking to reduce costs or overhead while obtaining 360-degree visibility into how their products go from point A to point B.

Rapid payback time

Passive RFID tags are becoming increasingly popular as a cost-effective technology due to their ability to facilitate efficient operations. From inventory tracking and data gathering to tamper-proof authentication, Passive RFID tags offer an array of advantages that can guarantee substantial cost savings and enhanced revenues.

Real returns on Passive RFID investments can be realized in terms of improved operational performance and customer experiences right away, making this technology one of the most practical solutions available.

Shorter processes

Passive RFID tags are an incredibly powerful tool for managing inventory workflows. By integrating this technology with other manufacturing or supply chain systems – such as automated pallet handling and stock picking – the time from order to delivery can be significantly reduced.

Passive RFID tags create real-time visibility within the production cycle and enable automatic data exchange between the physical and digital worlds, allowing manufacturers and companies to have greater control over their timeframes and processes. In today’s highly-competitive markets, using RFID technologies makes it possible for organizations to maintain a competitive edge while increasing efficiencies and optimizing business operations.

With the pervasive presence of RFID technology, businesses can now quickly and easily keep track of valuable items or assets with passive RFID tags. As this blog post has demonstrated, these advanced tracking technologies come packed full of useful features that provide greater convenience, security, and cost-effectiveness.

Application of RFID Tags

- How to Use RFID Technology in Libraries?

- Use of RFID Technology in Hospitals

- RFID Laundry Tags: Why You Should Use Them?

- Why You Need RFID Jewelry Tags?

- RFID for Files and Archives Management

- How to use RFID Tags manager Tools?

- How to Use RFID Technology for Cattle Tracking?

- Pros and Cons of Using RFID for Inventory Management

- How to Use RFID for Vehicle Tracking?

- Benefits of RFID Wristbands for Music Festivals

- How Does RFID for Manufacturing Work?

- The Benefits of RFID Ticketing Technology for Events

- 8 benefits of RFID in supply chain management and logistics

- How RFID Technology is Improving Sports Events

- Why RFID Wristbands are Integral for Small Events?

- How to use RFID Bracelets for Access Control?

- Benefits of Using RFID for Events

- Where is RFID Technology in your Life?

- How to Use RFID in the Food Industry?

- What is RFID Asset Tracking & How Does It Work?

- RFID Wristbands for Marketing

- RFID wristbands for Spa

- RFID Wristband For GYM

- RFID wristbands for theme parks

- Nike Integrates RFID Tags in Sneakers: Future of RFID in Footwear

- How An RFID Tire Tag Can Improve Your Business Performance

- What is WIP Tracking and How Does RFID Help?

Additionally, security concerns are rife with RFID technology. This is because RFID tags can be read without the owner’s knowledge or permission. As such, it is important to take measures to protect the data stored on RFID tags.

Despite these disadvantages, RFID tag is a popular technology that offers many benefits over traditional barcoding systems. If you are looking to track assets in your business, RFID tags are worth considering.