A work-in-process (WIP) tracking system helps organizations manage their production processes, including purchasing, manufacturing, and shipping. Many organizations use RFID technology to keep track of their WIP because it offers great accuracy and reliability. In this blog post, we’ll discuss why WIP tracking is important, how RFID can help you improve your WIP tracking process, and what benefits it will bring to your organization.

What is WIP Tracking?

WIP tracking systems are used to monitor the progress of a product from raw materials through every step in the production process until it is shipped out. The goal of these systems is to identify issues with production so they can be addressed quickly and efficiently. This helps reduce costs by ensuring that orders are completed on time and with minimal errors or delays.

How Does RFID Work?

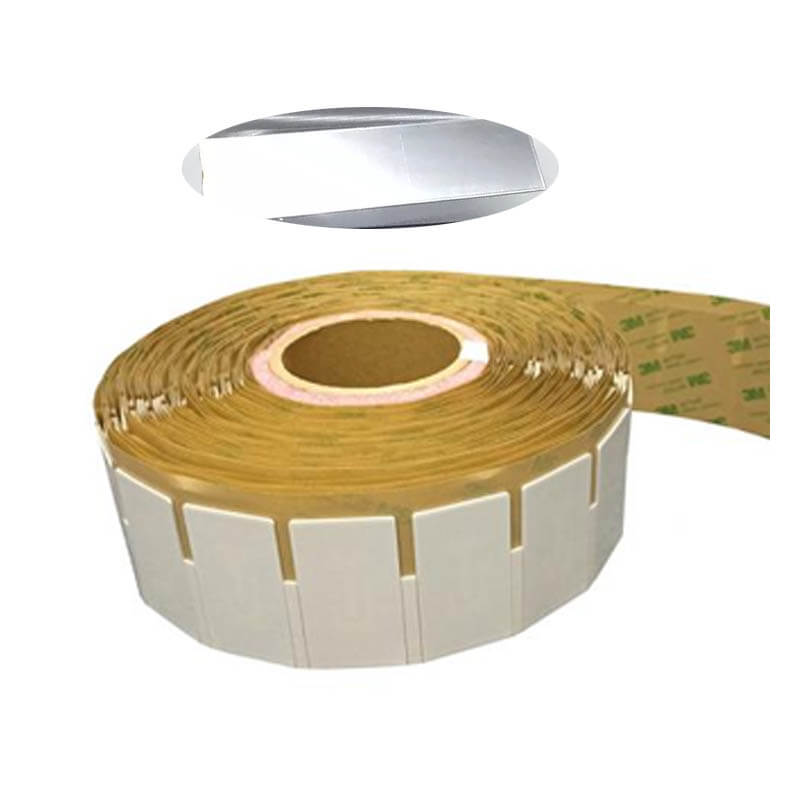

RFID stands for Radio Frequency Identification. It refers to a system whereby information about an item or product can be stored on an RFID tag that is attached to the item itself or embedded in its packaging. This data can then be read by special scanners called readers which transmit the data back to a central computer system for analysis. This allows companies to quickly and accurately identify items as they move through different stages of the production process, helping them keep track of their WIP more easily than ever before.

Benefits of RFID for WIP Tracking

Using RFID for WIP tracking offers several key benefits for companies who employ this technology:

- Increased accuracy – By using RFID tags instead of manual methods such as barcodes or paper-based systems, companies are able to get much more accurate data about their work-in-process items. This means that they can more easily identify what items need attention if something goes wrong during production or shipping.

- Improved visibility – By having access to real-time data about their work-in-process items, companies have a better understanding of where each item is in the production process at any given time – giving them greater visibility into the entire operation and allowing them to take appropriate corrective action if needed.

- Greater efficiency – By automating certain aspects of the work-in-process tracking system, companies can save time and money while still ensuring accuracy and reliability in their operations.

- Reduced costs – Automating certain aspects of WIP tracking reduces manual labor costs associated with manually entering data into spreadsheets or other programs – saving money in the long run while also improving overall efficiency.

The use of RFID technology for work-in-process (WIP) tracking offers many advantages for businesses looking to increase efficiency and reduce costs associated with their operations. By providing increased accuracy, improved visibility into operations, greater efficiency in data entry tasks, and reduced labor costs associated with manual entry systems; businesses are well served when using an RFID-based system for WIP tracking purposes. Investing in an RFID-based system may provide substantial returns over time as well as help streamline operations within your organization—allowing you to make better decisions faster!

Related articles:

- Why You Need RFID Jewelry Tags?

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- A Guide to RFID Tags Types And What are they Difference

- 10 Ways RFID Technology is Already in Your Life!

- RFID on Metal: A Few Things You Should Know about RFID and Metal Surfaces

- RFID for Files and Archives Management

- What Are RFID Tags and How Are They Used?