With the complexity of modern manufacturing operations, many companies find themselves bogged down by inefficiencies. But RFID technology is here to save the day!

By automatically tracking processes and information in real time, this powerful tool offers improved accuracy that can result in increased productivity. Consequently, this will lead to happier customers due to more accurate orders being shipped quickly. Let’s take a closer look at how exactly it works.

What is RFID Technology?

Radio Frequency Identification (RFID) technology is a wireless communication method that uses radio waves to transmit data about identified objects. It operates on the principle of electromagnetic induction and uses tags (small devices with an antenna and a chip) that can be either attached or embedded in various objects such as cards, animals, and inventory products. Read more.

How Does RFID for Manufacturing Work?

Radio Frequency Identification (RFID) technology is a wireless communication method that uses radio waves to transmit data about identified objects. It enables manufacturers to track and trace their products in real time and provides visibility over their production processes. To implement RFID technology for manufacturing, the following steps need to be taken:

- Preparation. The first step is to identify the type of product or objects you wish to track using RFID tags. This will determine what types of readers and tags are needed for your system. It’s also important to ensure that the RFID tags can withstand the environment in which they will be used, as well as any harsh conditions that may arise during the manufacturing process.

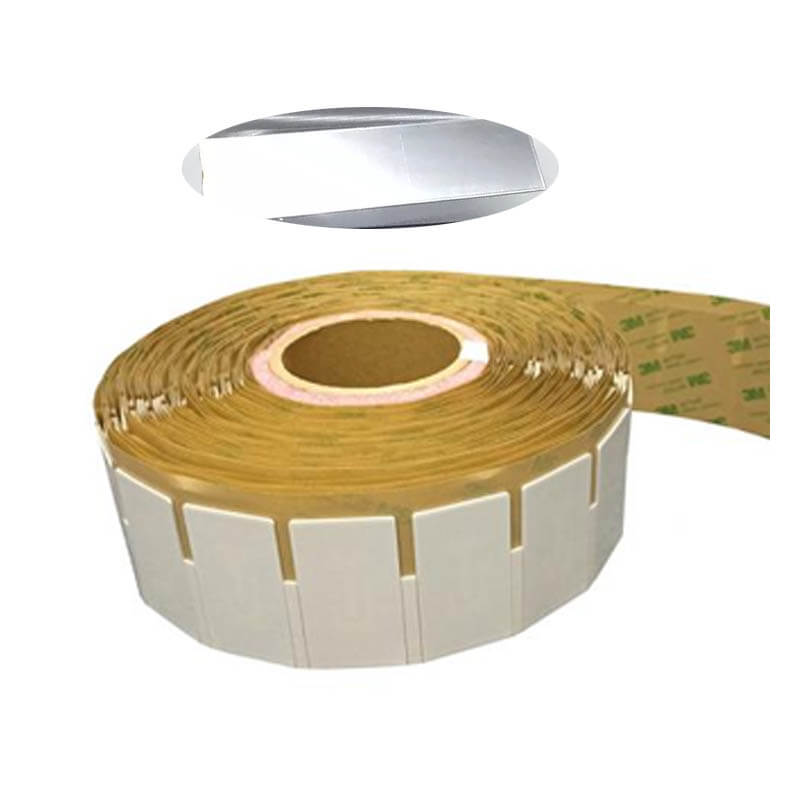

- Tag Attachment/Embedding. Once you have decided on the type of RFID tag that best suits your purposes, you need to attach or embed it onto the object or product being tracked (such as machinery parts, finished products, or components). This depends upon whether you choose active or passive tags for your system. Active tags often require additional wiring for power whereas passive ones use energy from an external reader device instead. Each tag needs a unique code so that it can be recognized when read by a reader device.

- Reader Installation. Next, install an appropriate reader at each stage along the production line so that it can detect any nearby RFID tags and gain access to their stored information. If more than one reader is needed, ensure they are properly connected to communicate within your overall system infrastructure.

- Data Storage & Analysis. Finally, collect all data sent by each reader device and store it in an information system where it can be analyzed and used to generate useful insights such as cost reductions or optimization plans for your production processes.

With this setup in place, you should then be able to monitor and manage different aspects of your manufacturing process with greater efficiency and accuracy compared to traditional methods – all thanks to RFID technology.

Benefits of Using RFID Technology for Manufacturing

RFID (Radio Frequency Identification) technology is an efficient way for manufacturers to track and trace their products in real time. It offers a range of benefits that can make production and supply chain operations faster, easier, and more secure. Here are some of the advantages RFID technology provides to manufacturing:

- Improved Accuracy and Efficiency. By automating data collection processes, RFID systems help to reduce human errors caused by manual data entry. This results in improved accuracy and faster processing of production line data which helps to optimize efficiency.

- Reduced Costs. RFID can lead to cost savings due to decreased need for manual labor & a reduction in inventory management costs thanks to improved visibility over inventory levels and tracking capabilities.

- Increased Visibility. With an RFID system, manufacturers access real-time information about their production process, allowing them to identify potential problems or delays before they become serious issues. This increases visibility into performance, quality control, and compliance matters for better decision-making capabilities.

- Improved Security. Compared with traditional methods, RFID technology offers more sophisticated security measures. For example, each tag or card must be authorized before entry into restricted areas – thus providing increased security against fraud or unauthorized access attempts.

- Enhanced Tracking Capabilities. An RFID system enables manufacturers to monitor the entire lifecycle of their products from order fulfillment right up until delivery – offering enhanced tracking capabilities which help improve customer service levels while reducing the risk of lost or stolen items along the way too.

How to Choose the Best RFID Tag for Manufacturing?

Choosing the best RFID tag for manufacturing comes down to understanding all the factors involved and selecting the tags that best meet your needs. Here are some of the key things to consider when making this choice:

- Materials. The material used for RFID tags can vary depending on their purpose. Epoxy-resistant tags are a popular choice due to their durability, while polyester & vinyl tags are affordable for one-time use.

- Frequency. Most RFID systems use two different frequency ranges – low frequency (LF) and high frequency (HF).

- Size. Consider how big or small you need your RFID tags to be, depending upon their placement and where they will be attached/embedded. Most manufacturers offer customization options so that tag size and shape can be tailored to fit specific requirements – something worth weighing up in advance too.

- Special Features & Functions. Different types of RFID tags can offer various special features, including temperature monitoring capabilities and an extended read range. Decide which ones you require ahead of time so that the correct tag type can be chosen for optimal performance outcomes.

- Cost. Don’t forget about cost when selecting the right RFID tag for manufacturing. Your budget will ultimately dictate how much you can spend on tag types, materials & any additional accessories required for installation.

Related articles:

- Why You Need RFID Jewelry Tags?

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- A Guide to RFID Tags Types And What are they Difference

- 10 Ways RFID Technology is Already in Your Life!

- RFID on Metal: A Few Things You Should Know about RFID and Metal Surfaces

- RFID for Files and Archives Management