RFID technology is becoming increasingly popular in the food industry for various reasons, including better inventory management, improved traceability, and streamlined supply chain processes. It is the perfect solution for identifying and tracking individual products, pallets, and entire shipments.

What is RFID in Food Industry?

RFID, or Radio Frequency Identification, is a technology that uses small electronic tags attached to products or packaging to transmit information via radio waves. This information can be read by an RFID reader and used for various purposes, including product identification and tracking.

To use RFID in the food industry, food companies simply attach RFID tags to their products or packaging. These tags can contain unique identifying information, such as a product’s expiration date, source, and location in the supply chain.

This way, They are able to follow certain goods and batches all the way from the farm to the retail shelf. It is a certain approach to guarantee food safety and legal compliance.

Components of RFID System for Food Management

An RFID system for food management typically includes three main components:

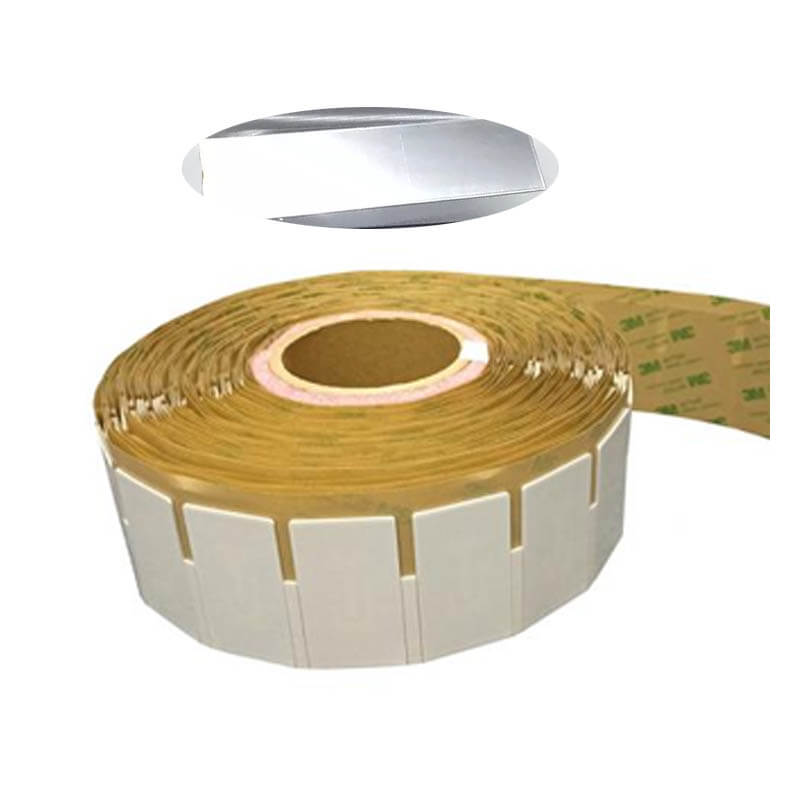

- RFID Tags. These tags have an antenna for receiving and transmitting radio waves as well as a chip with enough memory to retain information. It keeps track of specific details that make a product or delivery identifiable.

- RFID Reader. This tool receives data from RFID tags and transmits it to a network or computer for processing and analysis. Depending on the particular requirements of the food firm, it may be either a fixed RFID reader or a portable RFID reader.

- Software. The program organizes and analyzes the data collected from RFID tags, making tracking and administration simple. Moreover, it may alert users of any supply chain irregularities or the nearing expiry of a product.

For any system to work effectively, the three components must work together seamlessly. This is why it is critical to choose a reliable and experienced RFID provider for food management. Always ensure top-notch quality in both hardware and software.

5 Ways to Use RFID Tags for Food Management

RFID technology offers various benefits for the food industry, including:

- Supply Chain Management

Inadequate handling and storage practices can lead to damaged goods and safety risks in the food industry. Throughout the supply chain, real-time tracking of things using RFID tags makes sure they are always handled and kept correctly.

Every product is identifiable using distinctive RFID tags, making identification straightforward. RFID readers are also installed at multiple sites across the supply chain, including warehouses and distribution centers, for continuous tracking.

As a result, record-keeping is more accurate and effective, and any problems can be quickly identified and resolved. Also, it makes it possible for better forecasting and planning, which boosts the supply chain’s effectiveness.

- Inventory Management

RFID tags allow automated inventory management, eliminating the need for manual counting and record-keeping. This saves time and increases efficiency in warehouses and retail stores.

Retail stores can use RFID technology to track products on store shelves, allowing for instant notification of low stock levels and automatically updating inventory records.

- Product Traceability

In the event of a recall or contamination issue, RFID technology allows for quick and accurate tracing of affected products. This way, food companies can swiftly remove any potentially hazardous products from store shelves and notify customers.

RFID tags also allow for the tracking of specific ingredients or batches within a product, ensuring full traceability and compliance with regulations. This helps to maintain consumer trust and protect the reputation of the food company.

Even better, customers can scan RFID tags using their smartphones to access product information, such as source and expiration date. The detailed history and traceability of products give consumers peace of mind and promote transparency in the industry.

- Temperature Monitoring

Perishable food products must be stored and transported at certain temperature ranges to maintain quality and safety. RFID tags can be used in conjunction with temperature sensors to monitor the temperature at all times during transport and storage. This allows for immediate notification of any deviations, ensuring that products are not compromised.

Additionally, most temperature data loggers can store information and generate reports, providing a complete record for compliance purposes. The range can be −40 to 85 ◦C, depending on the specific needs of the food company.

Whenever temperatures go beyond these safe ranges, steps can be taken immediately to prevent potential safety issues. This also reduces the risk of spoiled and wasted products, resulting in cost savings for the company.

- Reduced Food Wastages

Accurate and efficient inventory management, along with temperature monitoring, can help to reduce food wastage. Real-time tracking allows for better forecasting and planning, reducing overstocking and expired products.

RFID tags also eliminate manual record-keeping, allowing staff to focus on other tasks such as shelf stocking and rotation. This results in better organization and fewer expired products, leading to reduced food wastage.

Choosing the Best RFID System for Food Management

When selecting an RFID system for use in the food industry, it is important to consider factors such as read range, tag durability, and compliance with regulations.

The read range should be sufficient for the specific company needs, whether it be for tracking pallets in warehouses or individual products on store shelves. In most cases, UHF RFID inlays with a longer read range may be preferable.

However, low-frequency tags can be used for short-range tracking in environments with metal or water, which may interfere with higher frequencies. It is also critical to choose tags that are durable enough to withstand the potential rough handling and harsh environments of food production or retail setting.

When it comes to compliance, RFID technology for the food industry must meet specific regulations set by organizations such as the FDA and GS1. These regulations cover factors such as data storage and security, product traceability, and temperature monitoring.

Working with a trusted RFID provider can ensure that the chosen system meets all necessary regulations and effectively addresses the specific needs of the food company. This way, businesses can reap the full benefits of using RFID technology in food management.

Related articles:

- Why You Need RFID Jewelry Tags?

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- A Guide to RFID Tags Types And What are they Difference

- 10 Ways RFID Technology is Already in Your Life!

- RFID on Metal: A Few Things You Should Know about RFID and Metal Surfaces

- RFID for Files and Archives Management

- What Are RFID Tags and How Are They Used?