Radio Frequency Identification (RFID) and barcodes are two of the most commonly used identification methods. Both have their advantages and disadvantages, so which one is the best option for your business?

This article compares RFID and barcodes in terms of accuracy, cost, and durability. We also discuss when you should use each technology. Read on to learn more!

What is RFID – Brief History

RFID technology is a part of Automatic Identification and Data Capture technology. In 1938, during an experiment with landline telephone systems, Bell Labs personnel found out that the sound from loudspeakers decreases if you put some metallic object on them. Later during the 1960s, this phenomenon was used to develop (passive) RFID tags and readers for automatic identification.

RFID tags store data (in the form of an ID) that can be scanned by an RFID reader. The most common example is animal tagging, where the technology is used to identify animals like cows and sheep with ear tags. This system began in 1971 when American Branders Association began using passive (battery-less) RFID tags. In 1980, NASA used active (battery-powered) RFID tags to monitor inventory movements in space shuttles. In 1983, the Electronic Product Code was designed for retail use and launched in 1994.

In 1991, a team of MIT students hacked into the supermarket’s laser checkout system, which made them independent of the clerk. This knowledge was later used in automatic toll collection systems, where it helps in vehicle identification on toll roads.

RFID tags are now widespread. They are used in hospitals for identifying patients, access control, and inventory tracking, among others

How RFID Works

RFID is a wireless technology that uses radio waves to identify and track objects. It takes advantage of the fact that all materials reflect radio waves, even if they do not conduct electricity.

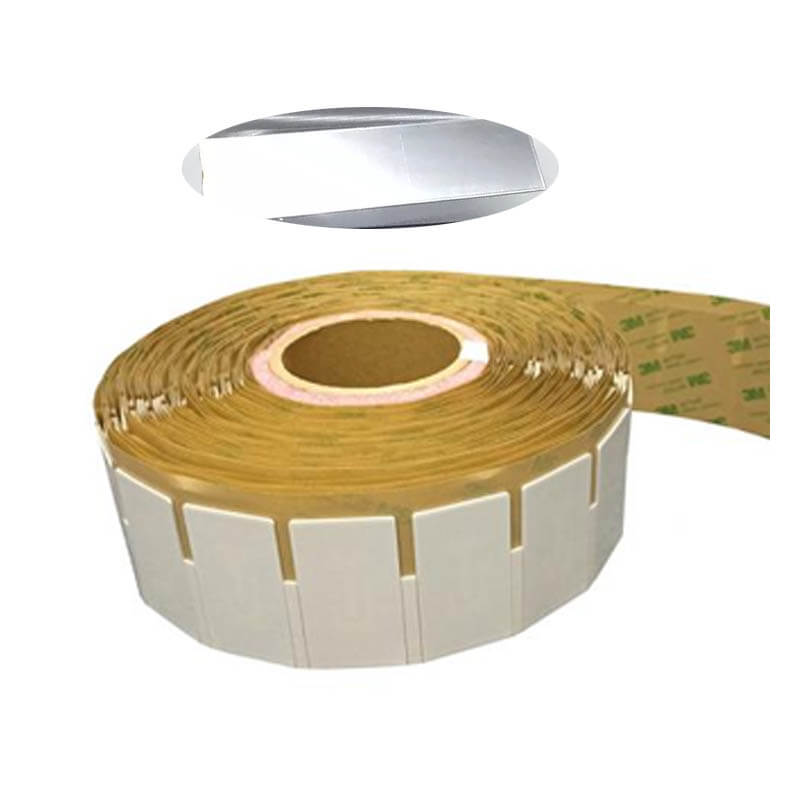

RFID tags contain a chip and an antenna for this purpose. They have enough memory to store unique identifiers or small amounts of other data. The chip communicates the data to a reader through the tag’s antenna.

RFID tags come in various form factors, but they are all based on three different working mechanisms:

- Passive Tags. These tags do not have a power source. They get all the energy necessary for operation from the radio waves generated by a reader device. Because of this, they have a limited range and must be within a few inches of a reader to transmit their data. Passive tags also have low memory, limiting the amount of information they can store about an object or event.

- Active Tags. These tags have their power source, often in the form of a lithium battery. As such, they can operate over larger distances. They also have more memory, which allows them to store detailed information about an object or event. However, they require additional hardware that increases their costs and decreases their reliability.

- Semi-Active Tags. These tags combine the features of active and passive tags. They receive power from a nearby source to create radio waves, but they also contain their batteries for operating independently. The batteries are recharged every time the tag transmits data back to the reader device.

Benefits of RFID Systems

RFID systems technology offers several benefits. Because RFID is an automated identification system, it can provide faster and more accurate inventory tracking than manual methods such as barcode scanning, which often must be backtracked manually. Other unique advantages of RFID systems over barcodes include:

- Greater Read Range.RFID systems can read tags up 100 meters away. This feature enables industries to use it for asset tracking and monitoring goods on transit.

- No Line-of-Sight Required.RFID tags can be read without the need to line up a barcode scanner and tag. As such, RFID readers can identify sideways, upside down, and stacked tags.

- No Tag Orientation Requirement for Readability.Tags do not have to be read as they pass by the scanner. Instead, they can be scanned at any time after they are in the range of the reader.

- No Shadowing Issues.Tags that are obscured or shaded can still be read because RFID systems utilize an omnidirectional antenna.

- High Reading Reliability.RFID systems can read tags even when pallets are moving at high speeds. This is advantageous over barcodes which suffer from lower reading reliability as speed increases (for example, due to poor contrast or smearing caused by rain).

- Minimal Operator Training.RFID systems require minimal operator training because the tags do not have to be perfectly aligned with scanners. This means that associates requiring no specialized training can read and record data during pick/put-away processes, reducing the reliance on supervisory staff for such tasks.

- Reduces Operational Costs.RFID technology automates shipping and receiving tasks, which would otherwise be labor-intensive. This automation can save companies time and money by allowing workers to focus on more value-added activities.

- Reduces ID Theft Risk.RFID tags do not contain any personal data, so they are immune from the risk of identity theft associated with magnetic stripes. This is important for healthcare applications.

Barcode Systems

The idea of a barcode is quite simple, but the journey to being able to use them in its current form was long and arduous.

The concept of using patterns made up of bars, or lines, which are read by machines to convey information was first theorized in 1879. The patent (No. 202193 for “Art of Compiling Statistics”), by Universal Postal Union employee, Friedrich Ludwig Georgii, was the first known patent for using bars to encode data. 5

In 1949, Bernard Silver and Norman Joseph Woodland of Drexel Institute of Technology in Philadelphia filed a patent which described a system of marking patterns on paper but did not go into wide use until the early 1970s, when devices to read the patterns were developed and became widely available.

Barcodes have been in use for decades, but they have advanced significantly since their introduction. Now, you can use barcodes for many purposes, including tracking inventory and ensuring security.

How Barcode Systems Work

A barcode system has a barcode and a reader. The readers scan the barcodes and then send the digital data to a computer system. Here, the data is decoded into its original form, making it easy to interpret.

There are two types of barcodes:

- 1-D barcodes

- 2-D barcodes

1-D barcodes include UPC and EAN codes. They have a single line of vertical bars that represent data. On the other hand, 2-D barcodes have multiple lines of stacked and interleaved symbols representing multi-dimensional pieces of information.

Additionally, 1-D barcodes depend on internet connectivity, while 2-D codes can work without the internet. As such, you should use 1-D barcodes if your data is likely to change frequently.

Benefits of Barcode System over RFID System

While an RFID system is better than a barcode system in many aspects, there are several aspects where the former beats the latter. Here are some of the advantages of barcodes over RFID systems:

- Scalability. Printing barcodes is far easier than attaching RFIDs to every product. Barcodes are printed on packaging by printers that are widely available in the market at low prices, making them affordable even for small retailers.

- Lower Cost. Barcodes are easier to implement, and they do not require wireless resources, which means that they work on wired networks only, minimizing the cost involved in the installation.

- Low Maintenance. Barcode systems do not require any maintenance, and hence the overall process is smooth.

- Convenience. Barcode scanners are inexpensive and can be easily replaced when broken. On the other hand, RFID has a high initial cost which means that they have to be taken care of very well to avoid excessive expenditure in replacement.

What Is the Difference Between RFID and Barcode?

Both technologies have been around for decades, but they have recently become more popular as manufacturing and retail industries adopt them. They both provide unique benefits, but they are better suited to specific tasks.

RFID has one primary benefit over barcodes: It can be used with all types of devices.

Barcodes are read by handheld scanners, which limits their use to point-of-sale systems and inventory tracking systems.

RFID tags also have more memory capacity than barcodes. If you are deciding between a barcode and an RFID system, you should assess your specific needs to determine which technology suits you the best.

How to Choose Between Barcodes and RFID Labels

Both technologies have their benefits and drawbacks, so choosing between them requires an evaluation of your specific needs. If you’re struggling to determine which would work best for your business, here’s a list of considerations to help you make a decision

- Data Capacity

If you need to store a lot of data in your inventory, then RFID tags may be the way to go. For example, if your company ships products internationally and need to keep track of product weights and dimensions for customs forms, RFID tags offer more options than barcodes do.

- Price

Barcodes are usually less expensive than RFID tags, but the cost of tags is slowly going down as more companies adopt them. In addition, some businesses may qualify for discounts on barcode and RFID tag purchases from third-party vendors.

- Where Will The Tags Be Used?

Tags can be used indoors or outdoors, so it’s important to consider the environment where they’ll be used. RFID tags can withstand hot and cold temperatures, making them ideal for outdoor use, while barcodes are better suited for indoor applications.

- Proximity

RFID readers must be within close range of their tags to read data. That makes it great for tracking objects as they move from one area to the next. Barcodes work well over larger distances, making them a good option if you need to track items across large warehouses or distribution centers.

- Efficiency

RFID tags are significantly more efficient than barcodes because they don’t require data to be sent via visual scans – everything is done wirelessly. Barcodes need to be scanned by humans, so it’s harder to find errors in data entry since humans aren’t perfect.

- Product Life

RFID tags are more expensive than barcodes, but they last longer. If you’re trying to decide between the two options for a product whose life span is 100 years or greater, then RFID tags will probably save you money.

- Device Compatibility

Barcodes are compatible with almost every mobile device, scanner, and printer available on the market today. RFID systems require specialized hardware. If you need your inventory tracked quickly, it might be difficult to find an RFID system that meets your needs.

When to Use Each Type of System

Based on the guidelines above, barcodes are best used for tracking products across shorter distances. They’re also helpful in environments where it’s easy to get dirty or lose tags. RFID systems work better in warehouses that require a larger range for inventory tracking. They can be less expensive than high-end barcode readers, and they’re compatible with a wide range of devices and software.

Choosing between barcodes and RFID tags can be challenging, but it’s an important decision for any business that needs to track inventory. Here are some key points to consider as you make your choice:

Barcodes offer faster data entry than RFID systems, making them better suited for shorter ranges.

RFID systems offer a wider range of capabilities, but they’re more expensive and harder to find than barcodes.

Barcodes are best for tracking products across shorter distances, while RFID excels at inventory tracking in warehouses.

Barcodes are compatible with nearly all devices, scanners, and printers on the market today. RFID devices require specialized hardware.

Barcodes are less expensive than RFID tags, but they wear out quickly. Tags last longer but are more expensive.

Be sure to consider your business objectives and needs before deciding which type of inventory tracking system is best for your organization. Whichever option you choose, the right software can ensure that you get the most value from your inventory tracking system.

Related Articles:

- What is the NDEF format?

- The Reason Why Everyone Love NFC Wristband

- 12 Best NFC Tag Uses That Will Make Your Life Fun

- How to Create Your Own Amiibo Card in 3 Simple Steps

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- 6 Crucial Factors that Affect RFID Read Range – A Detailed Guide

- LF, HF, and UHF Frequency: What’s the Difference?

- Active RFID Vs. Passive RFID: What’s The Difference?

- RFID Vs. NFC: What’s The Difference Between Them?