If you want to boost your profitability, you should invest in an RFID inventory management system. This technology allows you to capture, analyze, and use data when making crucial decisions. It automates your inventory, thus reducing the cost of labor and increasing accuracy.

But what are the exact benefits of investing in an RFID inventory management system? Does it have any disadvantages, risks, or limitations?

This article highlights all the pros and cons associated with the system. It gives an in-depth analysis of everything you expect before and after installing your RFID inventory management system.

Pros of Using RFID in Inventory Management

An RFID inventory management system will improve your operations’ efficacy, enhance customer satisfaction, and guarantee accuracy in record management. Below are some of the significant benefits you’ll accrue by integrating RFID technology into your inventory management:

- Automated Data Collection

The process of collecting, processing, and storing data can be tricky if you’re using manual systems. It can lead to many security loopholes, which may result in data breaches.

If you’re finding it tough to collect and store your data, you should invest in an RFID inventory management system. This system will integrate software to analyze raw data to help you make crucial business decisions.

Additionally, an RFID inventory system will guarantee customer satisfaction since the time you’ll require to collect and collate data will reduce significantly. When you have a client’s data in the RFID system, it will take a few seconds to identify the client. A simple RFID tag will retrieve all the customer’s data, including personal details, last time of visit, and previous complaints, among many others.

- Reduced Labor Costs

Manual inventory management is time-consuming and labor-intensive. Simple data management tasks may require up to 8 employees working late into the night! This approach is cumbersome and expensive.

If you want to cut the cost of labor significantly, you should consider investing in an all-inclusive RFID inventory system. This technology ensures that one employee completes tasks that would otherwise require many people and long hours!

The cut in labor costs will improve your profitability. Even better, the improved data management system will win customer trust, thus guaranteeing more business.

- RFID Inventory Management System is Easy-to-Use

RFID inventory management is more straightforward than a barcode system. It does not require line-of-sight for the readers to capture data stored in RFID tags.

As such, it takes less time to capture and process data. Even better, an RFID inventory system allows you to scan multiple RFID tags simultaneously.

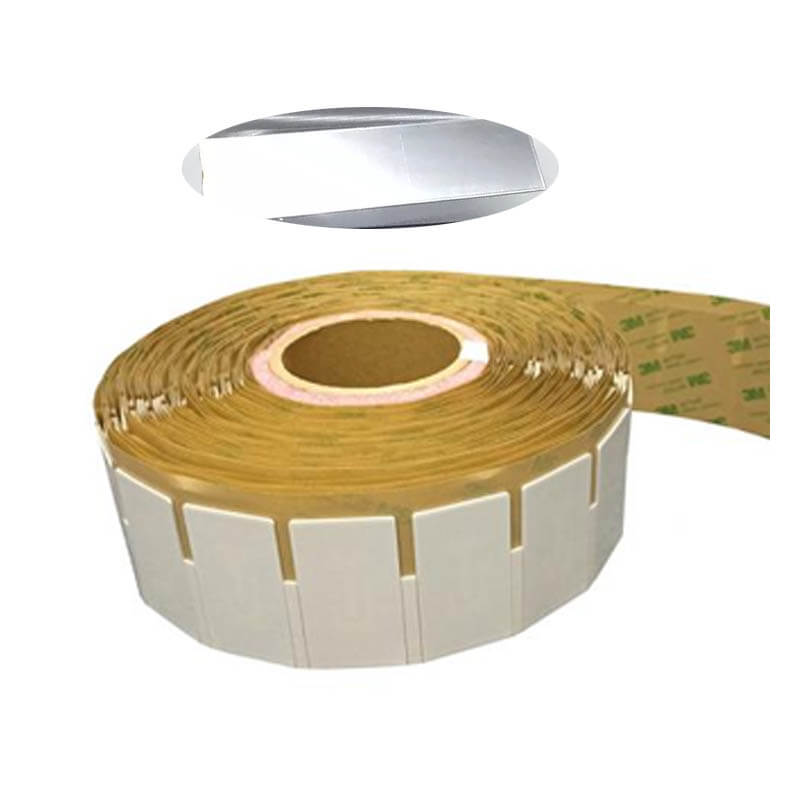

- Guaranteed Durability

A little grease or dirt on a barcode will render it useless.

That is not the case when using RFID tags! The tags are covered by hard materials such as plastic and metal, making them highly durable.

When you purchase your RFID tags from your nearest store, you can be sure that they will serve you for a relatively long time, depending on their nature. They are not affected by dirt, and the antenna will capture the reader’s signals nevertheless.

Additionally, it’s simple to customize RFID tags to work best in different environments. For example, you can purchase anti-metal tags or LF tags if you want to attach them to metallic and moisture-rich items.

- Enhanced Visibility

An RFID management system enhances the visibility of your inventory. All the data collected is visible to all authorized individuals (employees with a password to the RFID inventory software system).

All information that is captured by the RFID readers is processed and saved in the system. The visibility of your supply chain enhances accountability and eliminates the chances of theft.

Additionally, the enhanced visibility ensures that there is coordination among all departments in your institution. The procurement department can access the records for each department easily, thus ensuring that re-stocking is timely. It also prevents instances of overstocking since the procurement officer will not order items blindly.

- Holds Large Amounts of Data

Unlike a barcode, RFID inventory tags have larger memories. This feature enables you to store large amounts of data, thus creating a better inventory.

With the RFID tag system, you can include customers’ names, the last time they ordered, the product’s price, the product’s unique ID, and many other details. As such, you can be sure of an all-rounded data management system.

- Enhanced Decision Making

Investing in an RFID inventory management system helps you to make data-driven decisions. You’ll be able to understand the behaviors and preferences of your customers. The understanding helps you to make decisions that will improve customer experience, thus enhancing business prospects.

What are the Cons of RFID Inventory Management?

While an RFID inventory management system is undeniably beneficial, it comes with several disadvantages. They include:

- High Installation Cost

Implementing the RFID inventory management system requires high initial capital. You will be required to buy the following:

- Fixed or Handheld RFID readers, depending on your needs

- RFID tags

- RFID inventory software

These items will not necessarily be cheap, especially if you’re tracking many things. As such, you can be sure that the RFID system will be more costly than the barcode system. However, it will be worth every coin you spend on it since its benefits are long-run.

- RFID Tags Interference Can Wreak Havoc

RFID interference refers to any form of disruption that can decrease your RFID inventory management system’s functionality.

You should mainly be worried about the phenomenon if you deal with metallic or high-moisture products. Most of the UHF and HF tags will not work optimally in such environments. As such, you should always ensure that the tag you buy is either low frequency or a customized HF/UHF tag.

Additionally, RFID tags will be affected by other sources of radio waves. An environment full of radio waves will interfere with data transmission, thus compromising your RFID system’s overall functionality.

- Cost of Upgrading

You may be required to upgrade your RFID equipment to maintain efficacy. Changing the scanners and other elements of the system may be costly.

Additionally, whenever you add a department/in your organization, you will need to upgrade the RFID inventory system to capture and process the new department’s data.

- Compatibility Problems

RFID tags vary across industries, countries, and regions. As such, the application of an RFID inventory management system for an international business can be tricky.

If you were to succeed in the venture, you would require different RFID systems in different regions. This will increase the cost of operation.

What to Consider In RFID Inventory Management System

Before you decide on investing in RFID for inventory management, you should consider the following:

- Return on Investment. If the investment cost is higher than the expected returns in five years, you should avoid it.

- Standards and Regulations. Ensure that you buy RFID tags and equipment approved by your local/regional regulator

- Warehousing Volume. Ensure that you consider the volumes of items you want to track. The more they are, the higher the cost of installing an RFID management system.

Overall, RFID inventory management has more benefits than limitations. If you’re dealing with a large volume of data, you can be sure that it will enhance your operations and improve your profits.