Radio Frequency Identification (RFID) tags are used in a wide range of applications, from tracking inventory to providing identification for access control. But what exactly do these RFID Tags consist of? In this post, we’ll explore the various components of an RFID tag and the materials they’re made of.

The RFID Chip(IC)

An RFID chip, or integrated circuit, is a semiconductor device with a built-in logic and memory unit that can be used to store and process data.

An RFID chip typically contains an antenna that receives radio frequency signals from an interrogator antenna in order to retrieve data or receive control commands. It also contains a microprocessor for controlling the communication between the interrogator and the tag, as well as executing instructions on behalf of the user.

In addition, a secure element such as EEPROM or flash memory is present on most RFID chips to store information such as unique identifiers, passwords, and other sensitive data.

RFID chips are used in many applications such as access control systems, automated toll collection systems, vehicle tracking systems, library management systems, and asset tracking solutions.

A single RFID chip can contain multiple protocol stacks providing the ability to communicate with different readers using different protocols while still using the same physical device.

The usage of advanced encryption techniques makes it difficult to clone or modify data stored in an RFID chip without knowing its password.

The RFID Tag Antenna

RFID Tag Antennas are designed to have high sensitivity and directional characteristics. The design of the antenna is pivotal in optimizing the tag’s performance. Generally, the RFID tag antennas are designed with a spiral shape in order to maximize their signal reception capabilities. To further improve the antenna’s properties, multiple antenna elements can be used, such as dual dipoles or folded dipoles which enable a more focused signal reception in specific directions.

The material used for antenna construction is critical in ensuring proper operation. Metals such as copper, silver, and aluminum are preferred due to their excellent electrical conductivity and corrosion resistance qualities. Depending on the size and complexity of the RFID system, different methods may be used for constructing antennas such as copper etching, screen-printing, or foil stamping. Screen printing is typically faster than other methods since it does not require additional steps.

Further improvements can be made to RFID Tag Antenna designs by incorporating dielectric substrates which increase gain efficiency while reducing beamwidth and improving radiation patterns at higher frequencies. Additionally, careful consideration must also be taken when choosing the RFID tag’s operating frequency due to its impact on antenna design and overall tag performance.

RFID Tag Substrate

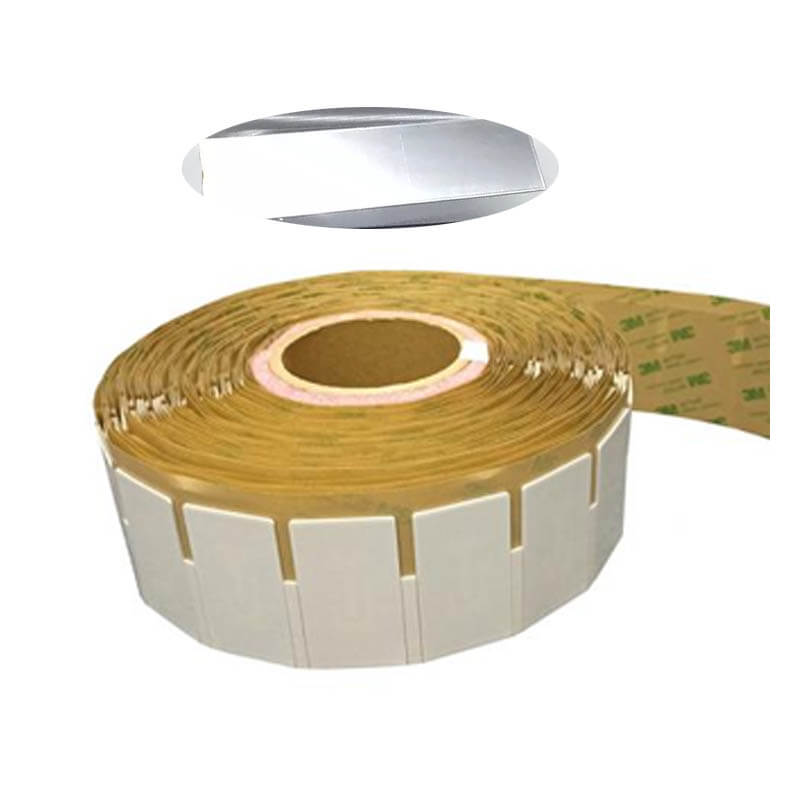

RFID tag substrates are an essential component in the RFID tag infrastructure. They provide support for other components, such as the antenna and integrated circuit (IC) chip, to be attached and properly function.

Depending on the application in which a passive RFID tag is used, substrates can either be rigid or flexible in nature. For applications requiring tags to be exposed to harsh environmental conditions, such as extreme weather or temperature fluctuations, flexible substrates have become increasingly popular due to their ability to withstand these elements.

Commonly used materials for RFID tag substrates include polymers like PVC and PET, styrene, phenolics, paper, and various other plastics.

RFID tag substrates are designed to be highly durable and resistant to a wide range of environmental conditions, including extreme temperatures, moisture, sunlight, chemical exposure, abrasion, and corrosion.

They also provide mechanical protection for the components and interconnections. One side is coated with an adhesive material to attach the tag to an object or surface. This adhesive is designed to ensure the RFID tag stays securely attached despite exposure to various environmental conditions.

Additionally, it is important that the substrate material provides a smooth printing surface for antenna layout design and dissipate any static buildup during operation. Lastly, it is essential that the substrate provides stability under different operating conditions.

Other Materials

Throughout the years, RFID transponders have been used for many different applications, so transponders have been embedded in hard plastic to protect them as well as ceramic to protect them from heat. Some tags can be embedded in metal—such as Armored-RFID tags—which makes them suitable for harsh environments where traditional tags would not survive.

Radio Frequency Identification (RFID) tags are small but powerful devices that allow us to track items with ease and accuracy. The key components of these devices include silicon microchips, antennas made from etched copper, aluminum, or conductive ink; PET/paper substrates; and labels printed with information about each tag’s contents.

Depending on how it will be used and what kind of environment it will need to survive in, there may also be additional materials required such as hard plastic or ceramic for extreme temperatures or metal for tough industrial settings. Understanding what each component does and how each material contributes helps us ensure our RFID tags will function properly no matter what conditions they may encounter!