Laundry is like playing with a burning torch – lost liners, increased costs, and tracking confusion. The advent of RFID laundry tags tracking technology has made laundry management a breeze. By tagging linens with radio frequency identification (RFID) chips, businesses such as hotels, hospitals and gyms can track every towel or sheet in real time. In this article we’ll look at how RFID can streamline the laundry process, reduce losses and increase efficiency. Ready to change your laundry game? Let’s explore what RFID laundry tracking technology can do for you and how to get started!

What Is RFID Laundry Tracking?

RFID laundry tracking uses small, durable tags sewn into linens—like sheets, towels, or uniforms—to store data such as item ID or wash history. These tags communicate with RFID readers, which send data to software for real-time tracking. Unlike barcodes, RFID scans multiple items instantly, even inside laundry bags, without needing line-of-sight. This means you can track hundreds of linens in seconds, know their location, and monitor their lifecycle. It’s a game-changer for high-volume laundry operations in hospitality, healthcare, or fitness centers.

Why RFID Laundry Tracking Is a Game-Changer

RFID brings serious benefits to laundry management:

- Real-Time Tracking: Know exactly where your linens are—laundry room, storage, or in use.

- Loss Prevention: Reduce linen loss by 20–30%, as RFID pinpoints missing items.

- Efficiency Boost: Cut inventory checks from hours to minutes with bulk scanning.

- Cost Savings: Optimize linen stock, extend item lifecycles, and lower replacement costs.

- Data Insights: Track wash cycles to predict maintenance or replacement needs. For example, hotels using RFID report saving thousands annually by reducing linen theft and overstocking.

How RFID Laundry Tracking Works

Here’s the simple process:

- Tag Linens: Sew or attach durable RFID tags (like TexBit’s UHF laundry tags) to items. These withstand heat, water, and chemicals.

- Use Readers: Handheld readers scan linens during sorting or transport; fixed readers at laundry chutes or exits automate tracking.

- Integrate Software: Data feeds into software like TexBit’s or Asset Infinity’s, showing item status, location, or wash count.

- Analyze Data: Use insights to optimize stock levels, reduce losses, or schedule replacements. This setup eliminates manual counts and keeps your laundry operation running smoothly.

Key Benefits for Different Industries

RFID laundry tracking shines across sectors:

- Hospitality: Hotels track linens to ensure guest rooms are stocked, cutting losses by 25% (per TexBit case studies).

- Healthcare: Hospitals monitor scrubs and bed linens to meet hygiene standards and avoid shortages.

- Fitness Centers: Gyms track towels to reduce theft and ensure availability for members.

- Laundry Services: Commercial laundries manage client linens, ensuring accurate billing and delivery. For instance, a hospital using RFID reduced linen replacement costs by 15% by tracking usage patterns.

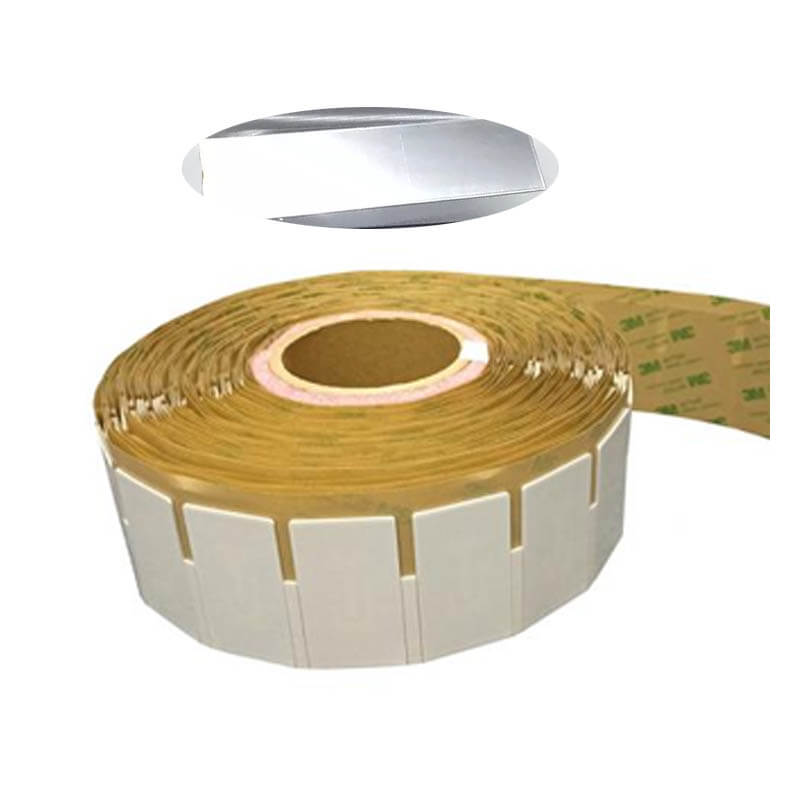

Types of RFID Laundry Tags

Choosing the right tags is crucial:

- UHF Laundry Tags: Long-range (up to 10 meters), ideal for bulk scanning in large operations. Cost $0.50–$2 each.

- HF Laundry Tags: Shorter range (up to 1.5 meters), better for secure, small-scale tracking.

- Durability: Look for tags rated IP68, resistant to water, heat (up to 200°C), and chemicals.

- Attachment: Sew-in tags for linens; adhesive tags for uniforms. TexBit’s tags are designed for 200+ wash cycles. Pick tags based on volume and environment—UHF for high-throughput, HF for precision.

Choosing RFID Readers for Laundry

Readers come in a few forms:

- Handheld Readers: Portable for sorting or inventory checks. Prices range from $500–$2,000 (e.g., Zebra’s RFD8500).

- Fixed Readers: Installed at laundry chutes or exits for automatic scanning. Cost $1,000–$5,000.

- Tunnel Readers: Scan entire laundry bags at once, perfect for high-volume operations. Choose readers that match your workflow—handhelds for flexibility, fixed for automation.

Steps to Implement RFID Laundry Tracking

Ready to start? Follow these steps:

- Assess Needs: Determine how many linens you track and your goals (e.g., reduce losses or speed sorting).

- Select Tags: Choose durable UHF or HF tags suited for laundry conditions. Test samples from suppliers like TexBit.

- Pick Readers: Handheld for small setups; fixed or tunnel for large-scale operations.

- Choose Software: Opt for platforms like TexBit or Asset Infinity that integrate with your ERP or billing systems.

- Tag Linens: Sew or attach tags to all linens. Start with a small batch for testing.

- Train Staff: Teach your team to use readers and interpret software data.

- Pilot and Scale: Test in one facility, then expand as you see results.

Costs of RFID Laundry Tracking

Here’s what to budget:

- Tags: $0.50–$2 per linen for durable laundry tags.

- Readers: Handhelds ($500–$2,000), fixed ($1,000–$5,000), tunnel ($5,000+).

- Software: $500–$5,000 for licenses or $50–$200/month for cloud-based.

- Setup: $1,000–$10,000 for installation and integration, depending on scale. Start with a pilot of 500 tags and a handheld reader to keep costs low, then scale up.

Challenges and How to Overcome Them

RFID laundry tracking has hurdles, but they’re manageable:

- Initial Costs: Tags and readers add up. Start small to prove ROI before scaling.

- Tag Durability: Cheap tags may fail after a few washes. Invest in high-quality tags rated for 200+ cycles.

- Interference: Water or metal can disrupt signals. Use anti-interference tags and test in your environment.

- Staff Training: New tech can intimidate. Offer hands-on training and simple software interfaces. Partner with vendors like TexBit or HID Global for expert setup and support.

Where to Buy RFID Laundry Tags and Equipment

Trusted suppliers include:

- TexBit: Specializes in laundry-specific tags and systems with proven durability.

- HID Global: Offers rugged tags for harsh environments, including laundry.

- Atlas RFID Store: Wide range of tags and readers with demos and support.

- Asset Infinity: Bundles tags, readers, and software for seamless integration. Compare prices, request samples, and check reviews to ensure quality.

FAQs About RFID Laundry Tracking

Q: How durable are RFID laundry tags?

A: High-quality tags withstand 200+ wash cycles, heat, and chemicals.

Q: Can RFID track linens in bulk?

A: Yes, UHF tags and tunnel readers scan entire laundry bags in seconds.

Q: Is it worth it for small businesses?

A: Absolutely—start with a small pilot to reduce losses and prove ROI.

Q: How do I choose a supplier?

A: Look for durability, support, and demos. TexBit and HID Global are top picks.

Start Your RFID Laundry Tracking Journey

RFID laundry tracking is your ticket to fewer headaches and more savings. From cutting linen losses to speeding up sorting, it’s a must-have for hotels, hospitals, and laundries. Start with a pilot, choose reliable suppliers like TexBit or Atlas RFID Store, and watch your operations transform. Ready to take control of your laundry? Contact an RFID expert for a free consultation and make laundry management a breeze in 2025!

Related articles:

- What are RFID Standards? An All-Inclusive Guide

- A Guide to Buying RFID tags and Equipment.

- Use of RFID Technology in Hospitals – 7 Things You Can Track

- Benefits of Using RFID Technology in the Clothing Industry

- LF, HF, and UHF Frequency: What’s the Difference?

- 10 Ways RFID Technology is Already in Your Life!

- What Are RFID Tags and How Are They Used?